| |

|

Manufacturing |

|

|

| |

|

|

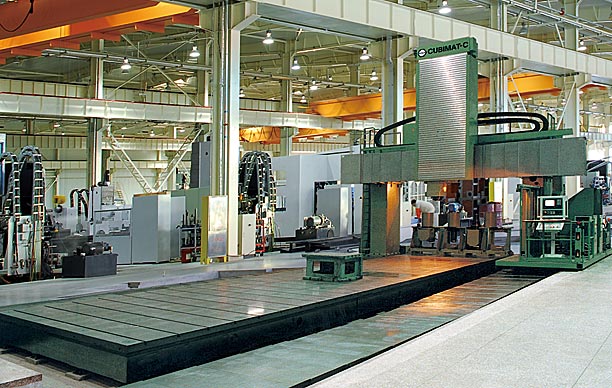

| Through the introduction of some advanced key equipments such as five-side machining centers, guide-way grinding machines, horizontal machining centers, CNC boring and milling machines, gear grinding machines with worm grinding wheel, CNC bending machines, CNC punch machines and three-coordinate measuring machines. The technology level of main parts of CNC machines such as large parts, box-type parts, main spindles has reached international level. |

|

|

| |

| Large-sized Gantry Type Five-slide Machining Center Imported from Germany |

|

| Through purchasing and importing more than 1,000 sets of electro-mechanical equipments and instruments, the flexible production capacity has been greatly increased, which have basically met the requirements of multi-models and small batch production of CNC machines. |

| |

|

| |

|

| |

|

| |

|

| |

|

| Nearly total 1 billion RMB has been invested in technology innovation by our company during the 8th Five-Year Plan and 9th Five-Year Plan, which makes the technology equipment level of our company ranks in the leading position in China; casting, sheet metal & fabrication and heat treatment technology rank in the advanced level in China. |

|

|

| |

|

| |

|

| More than 54,000 SQM purified and air-conditioned machining, assembly and commissioning workshops provide necessary guarantee in production environment for the machining and assembly of main parts and the commissioning of CNC system, thus realize the specialized production arrangements of main parts of CNC machines such as large parts, gears, box-type parts, spindles, guide-ways and CNC systems. |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| |

| |

|

|

|

|